How we developed a CRM system for a printing house, due to which we eliminated warehouse losses due to the human factor by 90%

Proper management of stock, supplies, goods and materials is a key factor in the success of a manufacturing enterprise. According to the statistics, 3 out of 5 errors in working with the resources of a manufacturing enterprise are due to the human factor.

Key causes of warehouse losses:

- Damage of materials and stock during improper storage at the warehouse;

- Damage of production as a result of expired raw materials usage, defects due to improper storage;

- Losses as a result of theft;

- Errors when entering information about arrival of the goods and materials at the warehouse/production.

- Errors in the labeling of raw materials and materials at stock.

- Errors as a result of lack of inventory or incorrect reconciliation check of information with the database.

At the same time, the key losses are felt by companies that sell goods and products directly to order, without mass production and the availability of ready stock at the warehouse.

At the beginning of 2014, the management of a large printing house asked us to find a solution to a number of production and accounting problems.

- Material accounting.

As a printing house is a manufacture that deals with production directly to order, most of the company's profit depends on the availability of the necessary raw materials of a proper quality at the warehouse when getting an application from a client.

But at the warehouse of the printing house there were problems with expiration of stocks, excessive consumption of raw materials stock by employees for personal purposes. As a result, the company lost up to 40% of orders because of the lack of necessary materials at the time of production, inadequate planning of work processes.

- Optimization of personalized analytics.

Due to delays of orders, the search of expeditious deliveries of new raw materials, the costs of acquiring new equipment, the company faced difficulties in predicting profit for each urgent order. In 10% of cases, according to the analysis after the order had been closed, the company fulfilled the application without income for the printing house.

- Automation of statistics on labor resources.

The lack of regular orders and production standards for each individual employee complicated the analytics of labor resources. The introduction of an individual form of statistics was required, taking into account the profile differences of the business.

A CRM system that improves report accuracy by 42%

As a solution, company “General Soft” proposed the development of a CRM system that can provide twenty-four-hour monitoring of materials at stock: paper, laminating films, bookbinding and calendar springs, grommets, and other materials. In addition, the implementation of an integrated electronic accounting system can generate personalized analytics for each of the orders received and keep accurate statistics on the performance of each employee. Such a solution will fully optimize the entire material accounting system and reduce the number of errors and losses due to the human factor in production.

Referring to the statistics of the analytical agency Reviev 42, the proposed CRM system will increase the number of sales of the printing house by 29%, i.e. bring the company, in terms of $ 1 investment in software, up to $ 8.71 of profit.

A solution for a manufacturing enterprise that will allow to retain and to increase the number of customers due to a better monitoring system

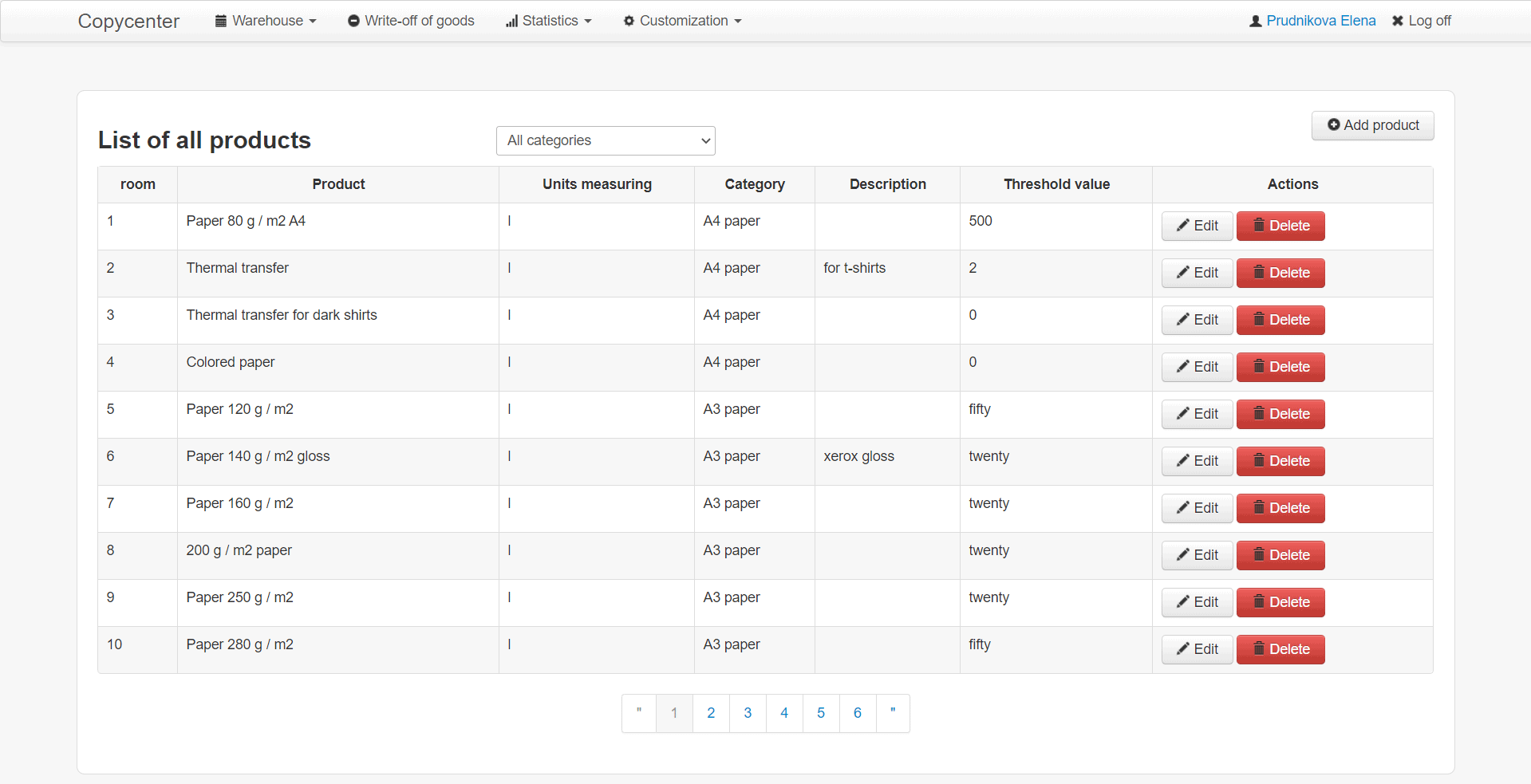

The introduction of a printing system was based on the integration of 3 main modules:

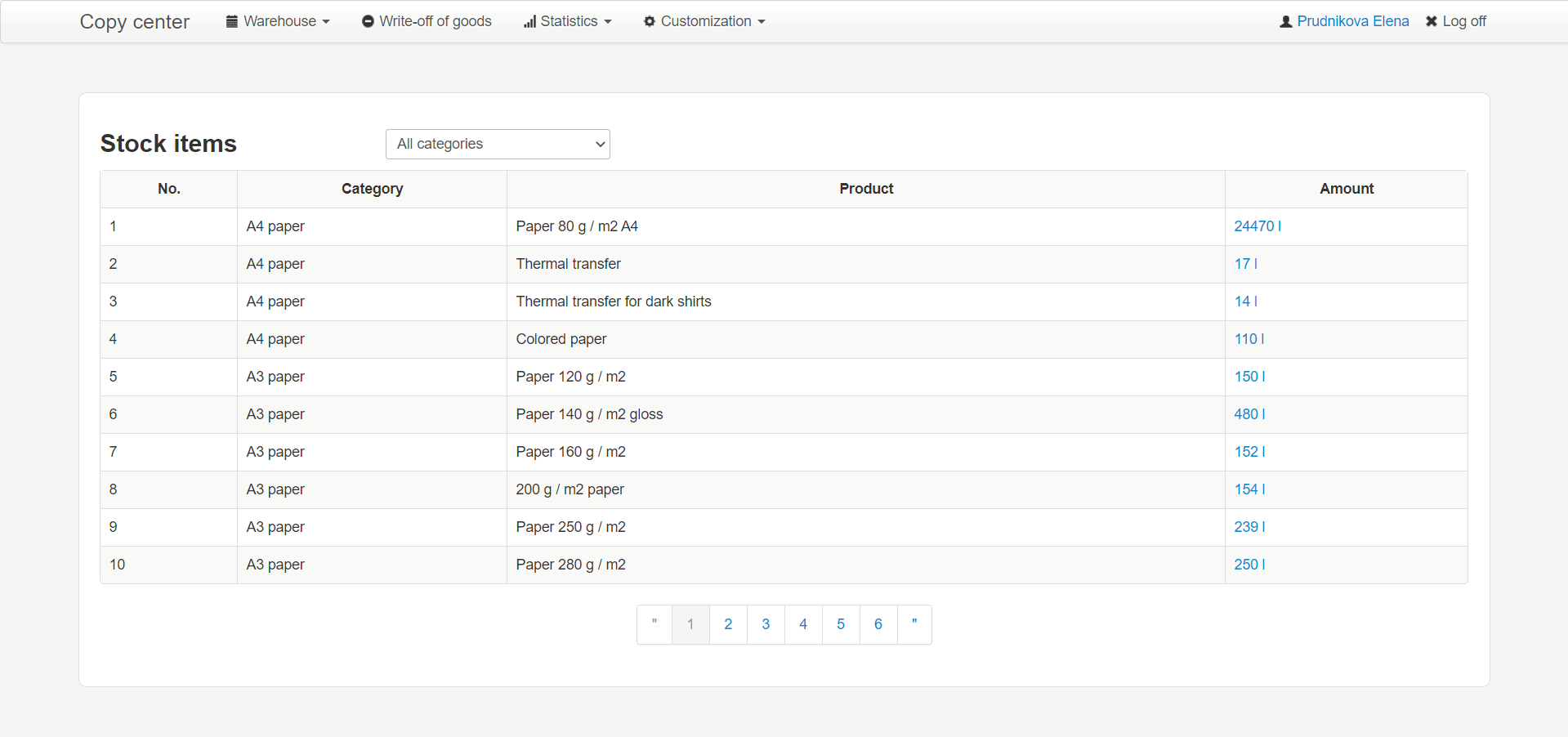

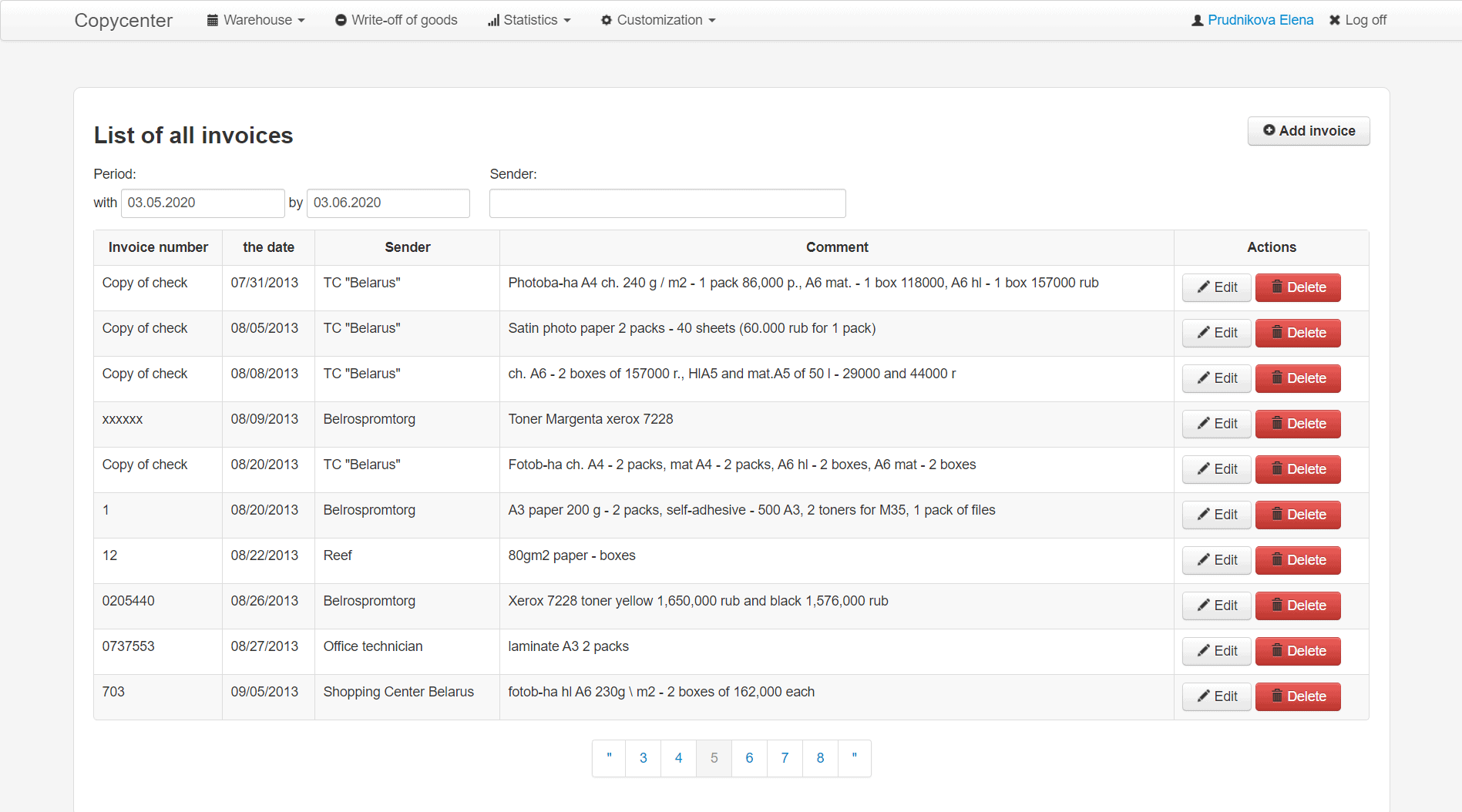

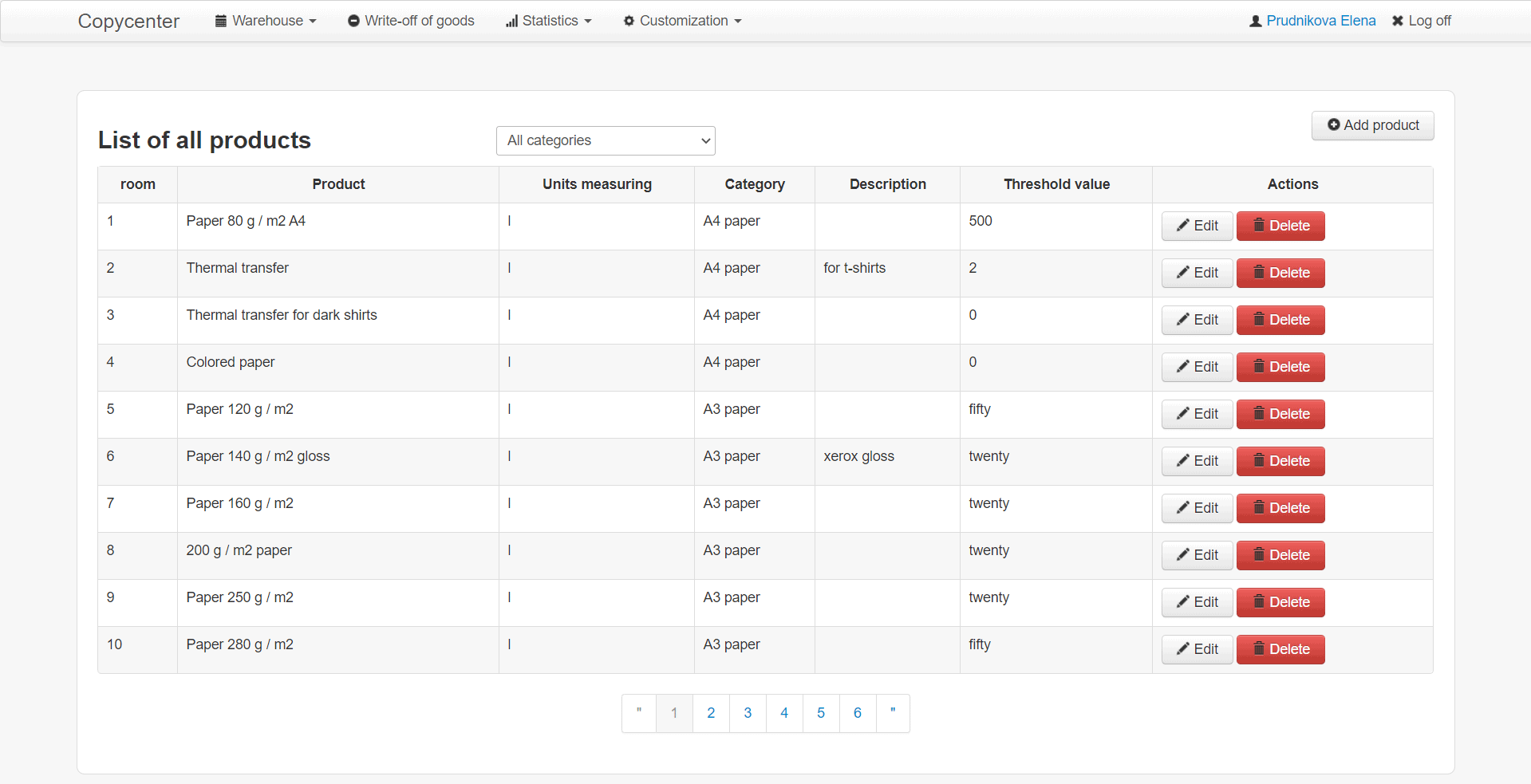

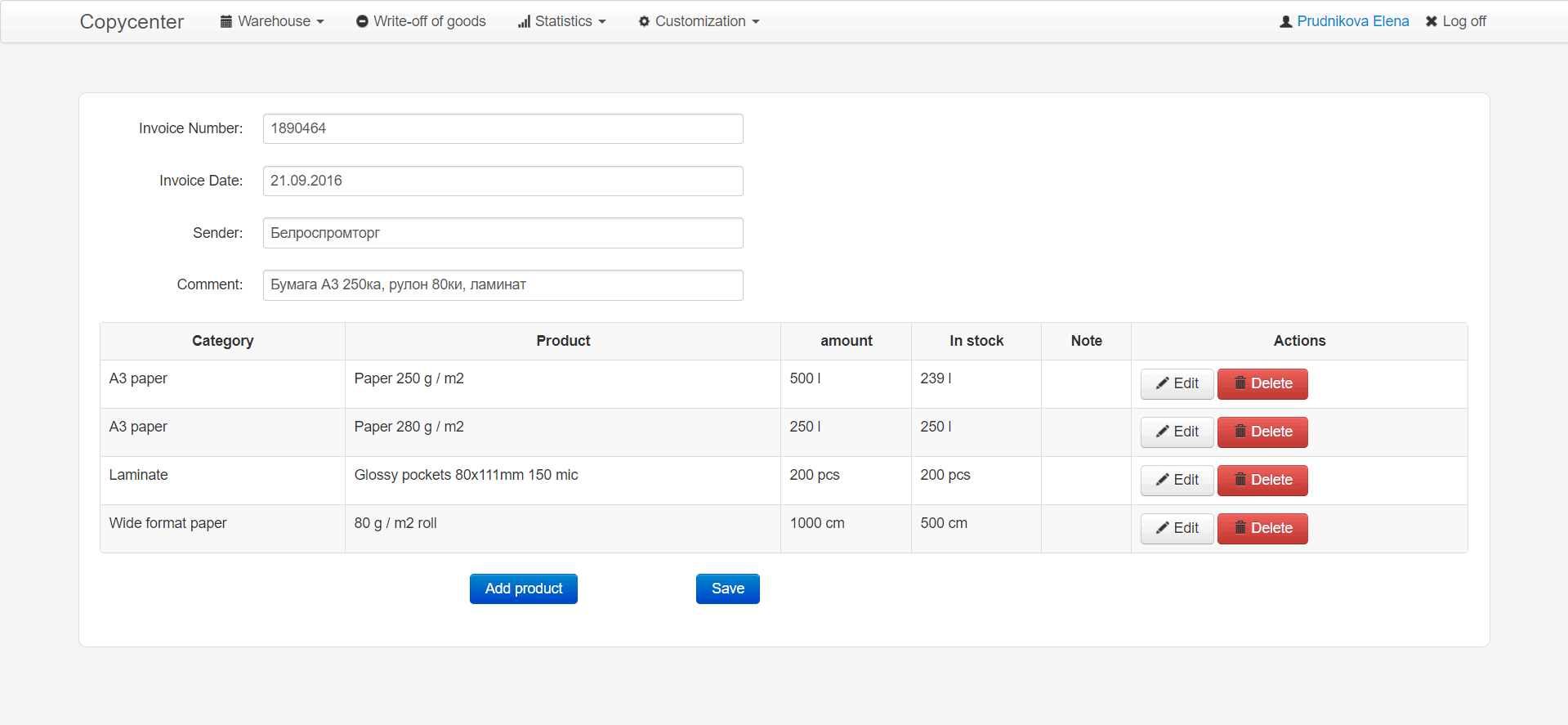

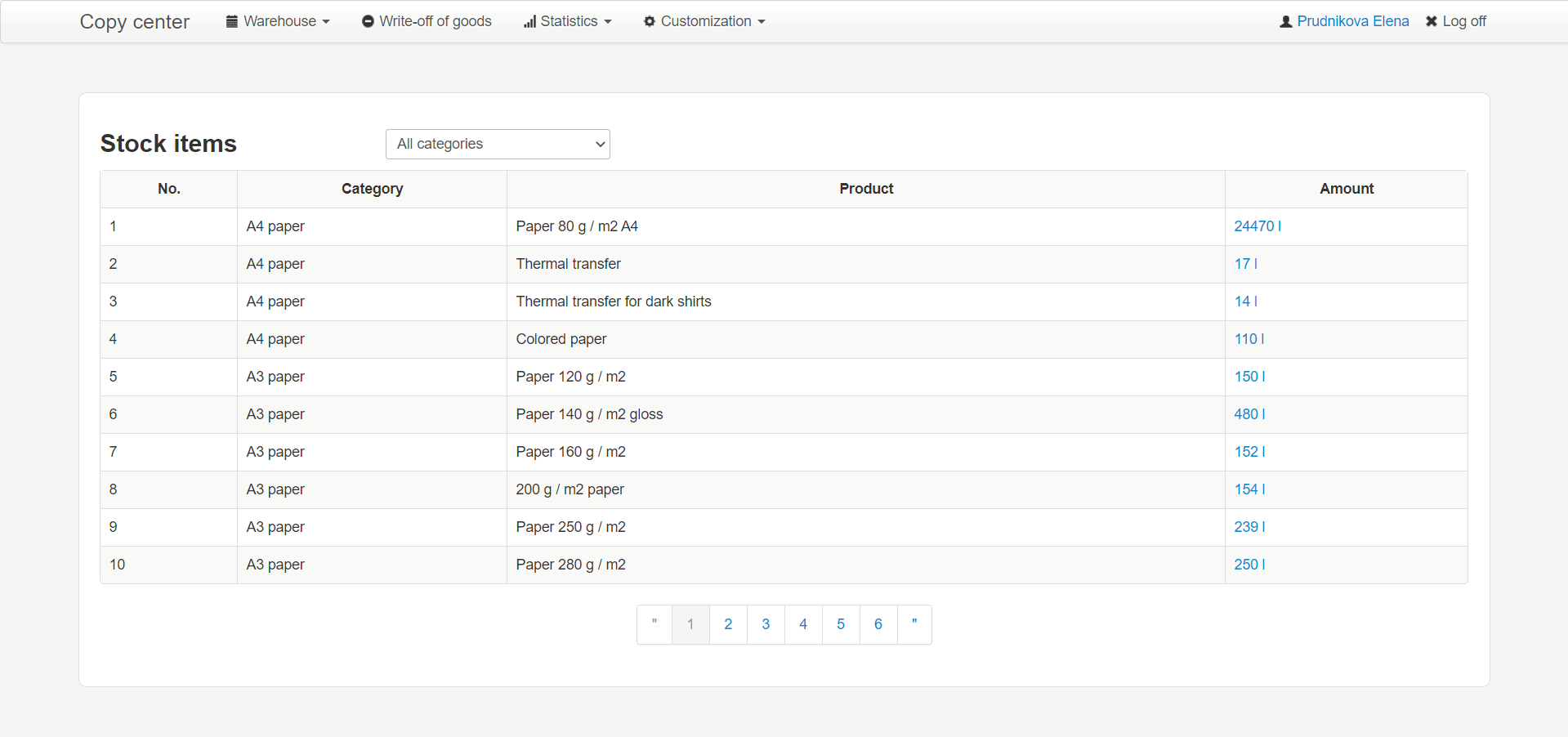

1. The system of stock storage. The arrival of raw materials was controlled by invoices, accounting of goods, and minimum of stock norms. This allowed immediately after goods entering to operate with current stock at the time of new orders arrival.

2. The system of goods writing off. This module defines items for writing off raw materials for the specific needs of the company, also as a result of defect or damage. Only the system administrator has access to the module, which excludes the change at the warehouse stock in the database by other employees. This allowed us to identify disadvantages in the norms of raw material storage and reduce the number of losses.

3. The system of statistical reports. The module allows you to monitor expenses and to predict profits for a specific period for specific items, taking into account the production chain of the company. It allows you to plan purchases, to generate minimum stock norms, to keep statistics on the workload of specific workers, and to monitor the number of available defects.

Results:

As a result of creating an individual solution for the printing house, the company, according to the feedback, was able to monitor the number of inventory items at the warehouse regularly, as well as to organize reporting in the areas necessary for the company. Thus, the company, due to the optimization of the workload for employees and the retraining system, was able to increase profits significantly and to reduce costs due to the human factor, in average, by 90%.